Operations

Operational insight that replaces guesswork with clarity

What It Does

Know what’s happening now

Monitors incoming loads through AI material recognition, flags bottlenecks, and protects inventory accuracy across single or multi-yard operations.

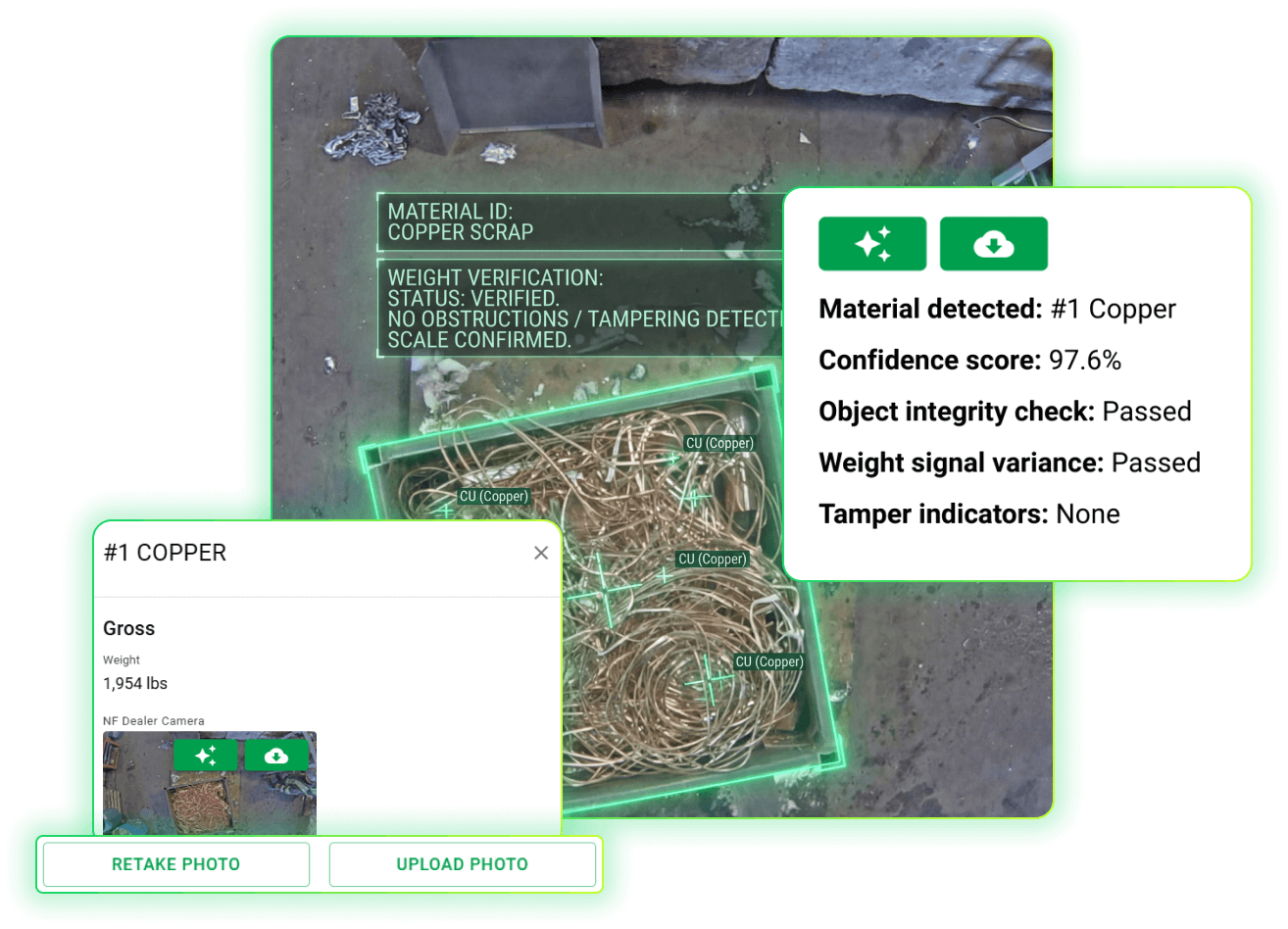

Inbound anomaly detection

Flags unusual loads, material mismatches, or scale irregularities using material recognition at the point of receipt.

Supplier BOL processing

Ingests and reconciles supplier paperwork against tickets and weights to reduce manual checks.

Bottleneck identification

Detects slowdowns and imbalances before they impact throughput.

Operational recommendations

Suggests rebalances, processing adjustments, or resource shifts to keep material moving.

Business impact:

- More consistent throughput and production planning.

- Early detection of operational risks.

- Improved inventory accuracy across yards.

Human benefit:

- Teams gain visibility into what requires attention and why.

- Managers start each shift with a clear plan instead of firefighting.

- Less time spent chasing issues, more time improving operations.

Start saving today Find out how much switching to

Find out how much switching to

GreenSpark can save your yard

Understand the real financial impact of running your yard on GreenSpark. Put clear numbers behind efficiency, accuracy, and control.